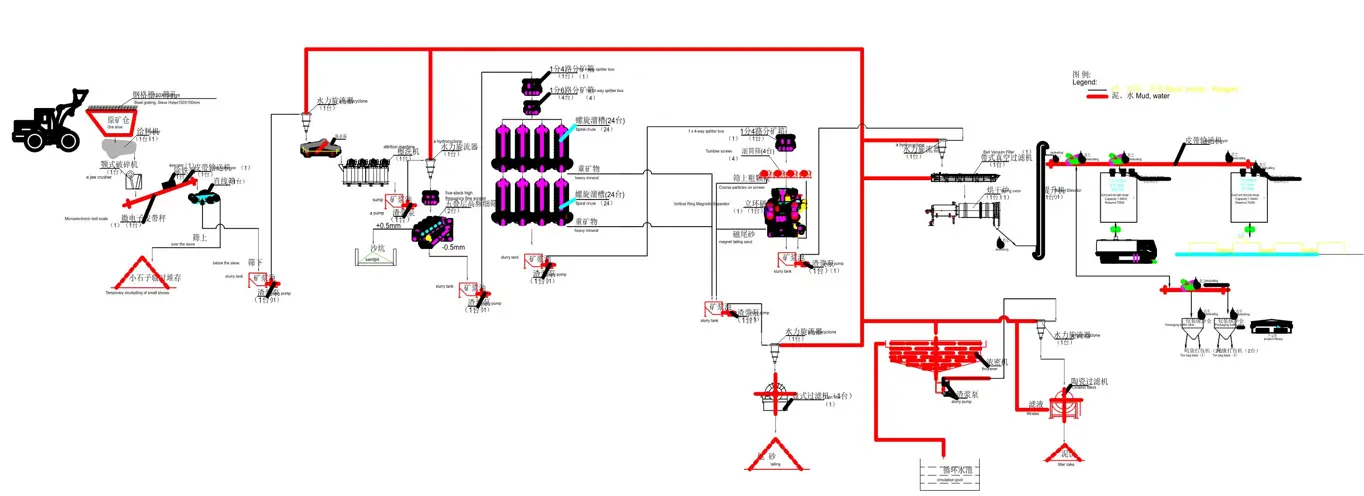

Silica Sand

Production Line Solution

A New Generation of High-Quality Silica Sand Processing System

Efficient • Eco-Friendly • Intelligent

Silica sand (also known as quartz sand) plays an increasingly vital role in high-value industries such as glass, ceramics, casting, photovoltaics, electronics, and chemicals. With stricter standards on particle shape, purity, and gradation, the demand for specialized processing solutions is rising.

If you want to know how to choose or design the crushing plant, please contact us, we will give our most professional suggestions or design.

Leveraging years of expertise in mining machinery, SBM has developed a complete silica sand processing line tailored for deep processing, delivering intelligent, efficient, and environmentally friendly solutions.

here are some typical outputs from our SBM system

Smooth, Efficient, and Precisely Controlled

Smart Integration, Superior Performance

Stable • Productive • Energy-Efficient • Eco-Friendly

High Wear Resistance

High Wear ResistanceKey components made of imported wear-resistant materials extend service life by over 30%.

Low Energy Consumption

Low Energy ConsumptionAdvanced control systems reduce overall power usage for greater energy efficiency.

High Automation

High AutomationSupports DCS/PLC remote control, one-button start/stop, and fault alarms for smarter plant operations.

Compact, Space-Saving Layout

Compact, Space-Saving LayoutModular designs make installation and commissioning easier, while reducing civil construction costs.

High-purity silica sand is a core material for solar and ultra-clear glass production.

Essential for electronic-grade silicon, chip substrates, and precision capacitor fillers.

Improves body density and whiteness while minimizing sintering defects.

Offers excellent thermal shock resistance, ideal for precision casting molds and cores.