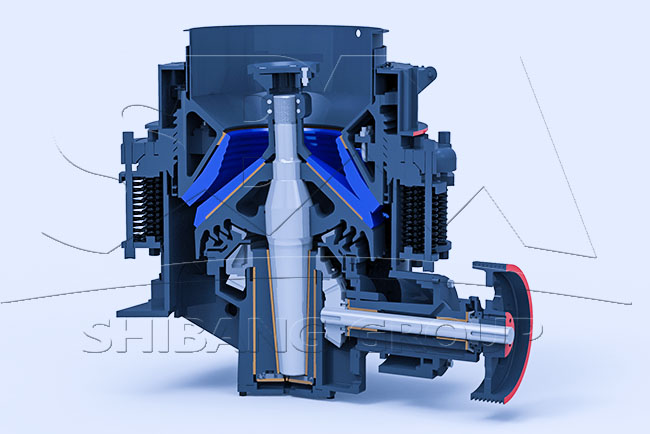

The PY series spring cone crusher has a simple structure, and after years of application and testing, it is reliable, economical, and has low maintenance and operating costs. With a variety of models available, it is suitable for crushing various ores and rocks with medium to high hard ness.

If you want to know how to choose or design the cone crusher, please contact us, we will give our most professional suggestions or design.

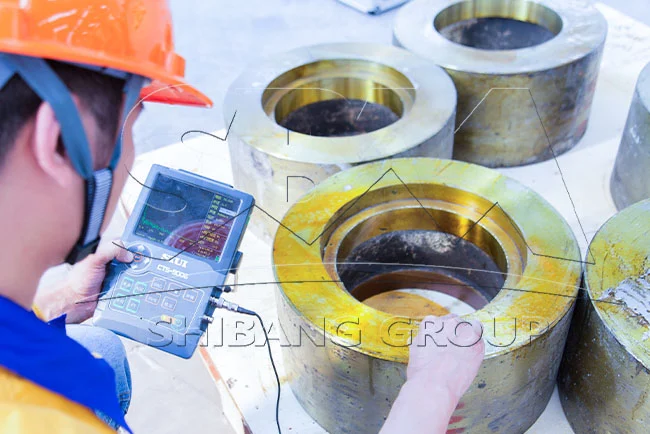

The traditional spring cone crusher technology is adopted, featuring a simple structure and more mature manufacturing techniques. It can use either dry oil or water sealing methods, ensuring more reliable performance.

Thanks to its simpler structure, the spring cone crusher has fewer failure points, making operation easier and reducing maintenance and operational costs.

Equipped with a spring safety system, which acts as an overload protection device, the crusher can allow foreign objects or iron pieces to pass through the crushing chamber without damaging the equipment.

The equipment comes with a variety of models to meet different process requirements. The standard type is suitable for medium crushing, while the medium and short head types are ideal for fine crushing.

| Model | Max Feeding Size (mm) | Output Size (mm) | Capacity (t/h) | Power (kW) |

|---|---|---|---|---|

| PYB600 | 65 | 12-25 | 40 | 30 |

| PYZ600 | 35 | 3-13 | 5-23 | 30 |

| PYB900 | 115 | 15-50 | 50-90 | 55 |

| PYZ900 | 60 | 5-20 | 20-65 | 55 |

| PYD900 | 50 | 3-13 | 15-50 | 55 |

| PYB1200 | 145 | 20-50 | 110-168 | 110 |

| PYZ1200 | 100 | 8-25 | 42-135 | 110 |

| PYD1200 | 50 | 3-15 | 18-105 | 110 |

| PYB1750 | 215 | 25-50 | 280-480 | 160 |

| PYZ1750 | 185 | 10-30 | 115-320 | 160 |

| PYD1750 | 85 | 5-13 | 75-230 | 160 |

| PYB2200 | 300 | 30-60 | 490-750 | 260-280 |

| PYZ2200 | 230 | 10-30 | 200-580 | 260-280 |

| PYD2200 | 100 | 5-15 | 120-340 | 260-280 |