Silica Sand Production Line Solution

Efficient · Eco-Friendly · Intelligent

A New Generation of High-Quality Silica Sand Processing System

Rising Value of Silica Sand Calls for Professional Processing Equipment

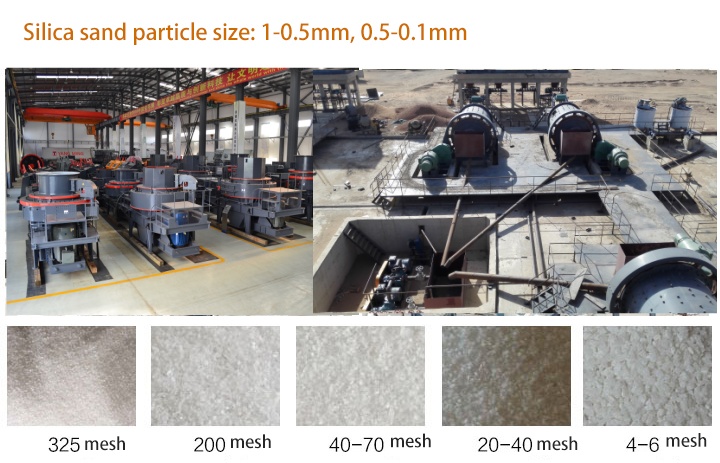

Silica sand (also known as quartz sand) plays an increasingly vital role in high-value industries such as glass, ceramics, casting, photovoltaics, electronics, and chemicals. With stricter standards on particle shape, purity, and gradation, the demand for specialized processing solutions is rising.

Leveraging years of expertise in mining machinery, SBMX has developed a complete silica sand processing line tailored for deep processing, delivering intelligent, efficient, and environmentally friendly solutions.

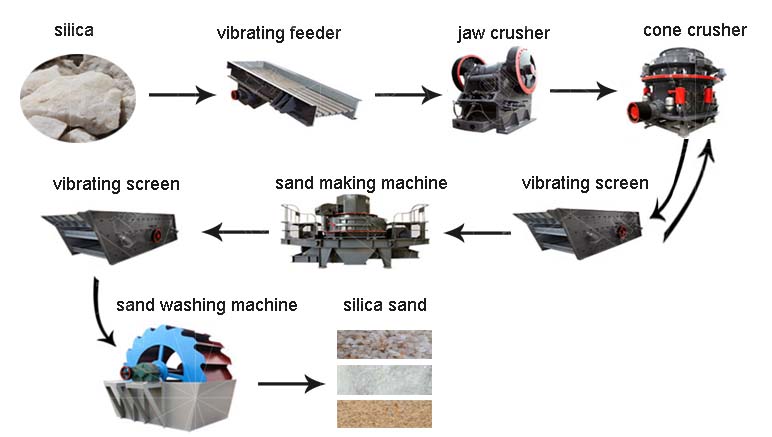

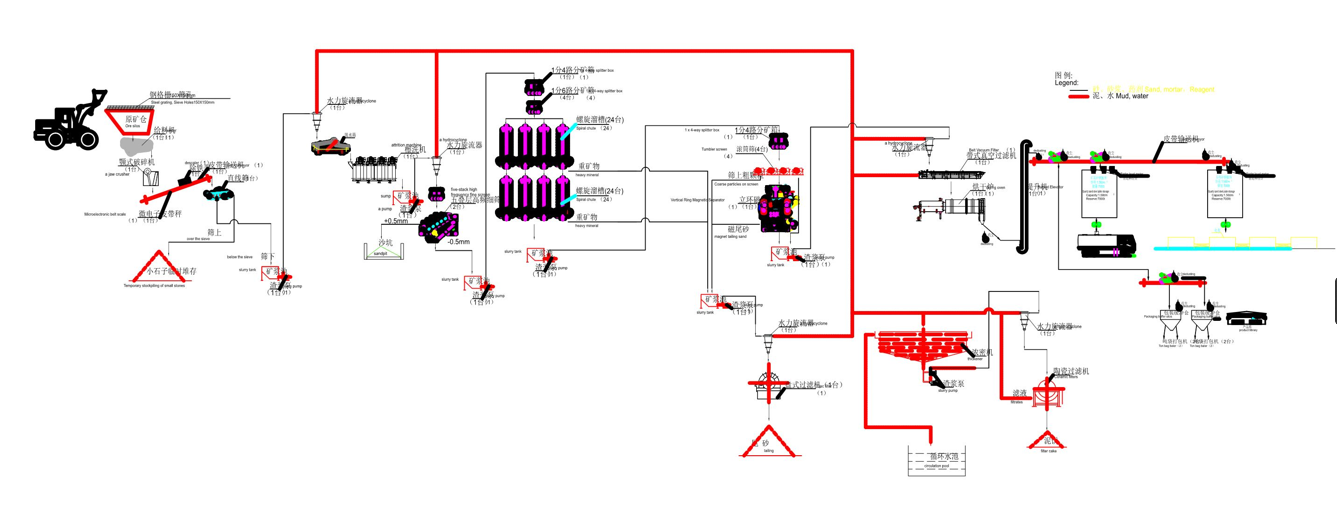

Process Flow | Smooth, Efficient, and Precisely Controlled

- Vibrating Feeder

High-efficiency feeders deliver raw ore evenly to jaw crushers, avoiding blockages and uneven loading. - Primary & Secondary Crushing

Heavy-duty and fine jaw crushers ensure precise particle size control and maintain optimal grain shape. - Vertical Shaft Impact Crushing (VSI)

Using a “rock-on-rock + vortex chamber” principle, the SBMX VSI sand maker achieves excellent sand shape with a forming rate of 40%–50%. - Multi-Stage Screening

High-frequency circular screens remove non-conforming particles and work seamlessly with return systems for reprocessing. - Water Washing & Desliming

Wheel or spiral sand washers effectively remove silt and fine impurities, meeting photovoltaic-grade purity standards. - Dust Collection & Environmental Control

Pulse dust collectors and automated spray systems are deployed across the line to ensure clean, dust-free production. - Iron Removal

High-gradient magnetic separators eliminate magnetic impurities such as iron oxides to enhance purity. - Heavy Metal Removal

Chelation, acid leaching, or flotation systems remove heavy metals like lead, zinc, and copper as needed. - Drying

Three-cylinder or rotary dryers quickly remove moisture, making the sand suitable for packaging or further processing.

Equipment Highlights | Smart Integration, Superior Performance

- VSI Vertical Shaft Impact Crusher

Features independent oil lubrication, automated temperature control, and programmable startup. Ideal for medium-to-hard materials with stable performance and low maintenance. - ZSW Vibrating Feeder & Jaw Crusher

Built for heavy-duty operations with large feed capacity and deep crushing chambers — ideal for hard materials like quartzite. - XSD Wheel Sand Washer / LSX Spiral Sand Washer

Delivers high washing efficiency with a simple structure and low water use — perfect for high-purity silica sand. - GZD Circular Vibrating Screen

Offers precise screening, low noise, and easy screen replacement for versatile size control. - Dust Collection System

Features PLC-controlled pulse bag collectors combined with sealed conveyors and spray systems for a green production environment. - Scrubbing Machine

Uses high-shear agitation and inter-particle friction to remove surface contaminants — a crucial step in silica purification. - Settling & Retention System

Thickeners or settling tanks separate fines and allow for water recycling, significantly reducing water consumption. - Drying Equipment

Three-pass dryers deliver efficient drying with low energy usage, ideal for medium to fine silica sand.

Full-Line Advantages | Stable · Productive · Energy-Efficient · Eco-Friendly

- High Wear Resistance

Key components made of imported wear-resistant materials extend service life by over 30%. - Low Energy Consumption

Advanced control systems reduce overall power usage for greater energy efficiency. - High Automation

Supports DCS/PLC remote control, one-button start/stop, and fault alarms for smarter plant operations. - Compact, Space-Saving Layout

Modular designs make installation and commissioning easier, while reducing civil construction costs. - Cost-Effective with Full Support

Optimized configurations and lifetime technical service ensure reliable, worry-free operation.

Typical Applications of Silica Sand

- Photovoltaic Glass

High-purity silica sand is a core material for solar and ultra-clear glass production. - Electronics & Semiconductors

Essential for electronic-grade silicon, chip substrates, and precision capacitor fillers. - Ceramics

Improves body density and whiteness while minimizing sintering defects. - Casting Sand

Offers excellent thermal shock resistance, ideal for precision casting molds and cores.

Partner with SBMX and Unlock Premium Silica Sand Processing

At SBMX, we put our customers first — continuously optimizing equipment performance and process design. We aim to be your trusted, long-term partner in the high-end mineral processing sector.