Double-roll crusher is a classic equipment designed based on the principle of extrusion crushing

Double-roll crusher (referred to as double-roll crusher) is a classic equipment designed based on the principle of extrusion crushing. With core advantages such as simple structure, low over-crushing rate and precise particle size control, it plays an important role in medium and fine crushing operations in various industrial fields including mining, building materials, chemical industry and metallurgy, and is widely suitable for the diversified production needs of modern industry for high efficiency, energy saving and environmental protection. As a mature equipment that has undergone years of technological iteration, it not only retains the stability and reliability of traditional crushing equipment, but also adapts to more complex material crushing scenarios through material upgrading and structural optimization.

I. Core Structure and Working Principle

The double-roll crusher has a compact overall structure and reasonable layout of core components, mainly consisting of five modules: roller wheels, frame, transmission system, gap adjustment device and overload protection device. Among them, the roller wheels, as the core working components, are made of high-strength wear-resistant materials such as high manganese steel and wear-resistant alloy steel. According to the characteristics of the crushed materials, their surfaces can be designed into three forms: smooth surface, toothed surface and grooved surface. Smooth surface rollers are suitable for medium and fine crushing and grinding of medium-hard materials such as limestone and quartz sand; toothed surface rollers can enhance the biting force on viscous materials such as coal and shale, making them more suitable for rough crushing links; grooved surface rollers can improve the clamping force on bulk materials, avoid material slipping during crushing, and improve operation efficiency.

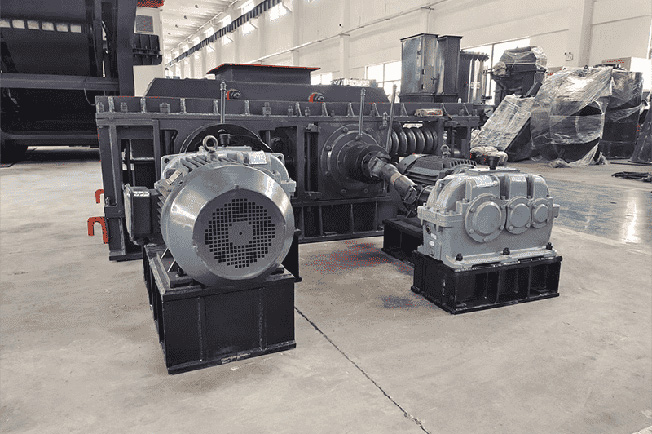

Its working principle follows the core logic of low-speed extrusion crushing: the motor drives two roller wheels to rotate at a constant speed in opposite directions through triangular belts or couplings. Materials fall vertically from the feed port at the top of the equipment into the V-shaped crushing cavity formed between the two rollers, and are gradually extruded and sheared to the required particle size under the static pressure continuously applied by the roller wheels. Materials with qualified particle size fall naturally from the discharge port at the bottom of the equipment under the action of gravity generated by the rotation of the roller wheels, completing the crushing process. To meet the requirements of different production scenarios for finished product particle size, the equipment is equipped with a wedge-shaped or gasket-type gap adjustment device. By rotating the adjustment bolt to lift the wedge block or increasing/decreasing the thickness of the gasket, precise adjustment of the roller gap within the range of 1mm-20mm can be realized, thereby flexibly controlling the discharge particle size. In addition, the overload protection device is the key to ensuring continuous and safe operation of the equipment, mostly adopting a spring or hydraulic structure. When uncrushable objects such as iron blocks and stones enter the crushing cavity, the spring is compressed to push the movable roller to retreat automatically, increasing the roller gap to allow foreign objects to be discharged smoothly; after the foreign objects are removed, the movable roller resets quickly under the elastic force of the spring, and can resume operation without manual intervention, effectively avoiding equipment damage due to overload.

II. Core Characteristics and Technical Advantages

Compared with impact crushers such as hammer crushers and impact crushers, the double-roll crusher shows significant advantages due to its unique crushing method. First, the particle size is uniform and the over-crushing rate is low. The low-speed extrusion crushing method avoids excessive impact and grinding of materials, resulting in very few powdery materials. The finished product has a high cubic content and stable gradation, which is especially suitable for operation scenarios with high requirements for particle shape such as sand and gravel aggregate preparation, ceramic raw material processing and refractory material crushing. Second, it is efficient, energy-saving and convenient for operation and maintenance. The equipment has a simplified structure, few transmission links, and energy consumption much lower than that of impact crushers with the same capacity; the core components made of wear-resistant materials have a long service life and low replacement frequency, and the equipment maintenance process is simple, which can greatly reduce the later operation and maintenance costs. Third, it has strong adaptability and flexible adjustment. It can widely process various materials such as coal, limestone, iron ore, gypsum and bentonite, and can efficiently crush brittle, medium-hard materials and slightly viscous materials. Combined with the flexible particle size adjustment function, it can meet the production needs of different industries, making it an ideal equipment with both reliability and practicality in the field of industrial crushing.